Energy consumption braking and reverse braking are bothBrake motorThe former has strong braking force, stable braking and no big impact. This method can make the production machinery accurately stop, but it requires DC power supply, and the equipment investment is large. This method can make the production machinery accurately stop. The latter has strong braking force, quick stopping, and does not require DC power.

The principle of energy braking is whenBrake motorAfter turning off the AC power supply, the rotor will continue to rotate because of inertia, at this time in the two-phase stator winding through direct current, the stator will produce a static magnetic field cutting this static magnetic field will produce induced current, by the effect of electromagnetic force, the torque generated and the rotor inertia rotation direction opposite, called braking torque, it forces the rotor speed down.

If the rotor speed drops to0Then the rotor will no longer cut the magnetic field, the motor will stop, and the braking will end. This method uses the energy of the rotor to cut the magnetic flux and generate the braking torque. In essence, the kinetic energy of the rotor is consumed on the resistance of the rotor loop, so it is called energy consumption braking.

Reverse braking is reverse braking power supply, when the rotating magnetic field is reversed, the direction of the rotor winding cutting magnetic field is opposite to the state of the motor, in order to achieve the braking effect, when the speed is reduced to close to zero, because the power supply is immediately cut off to avoid motor reversal.

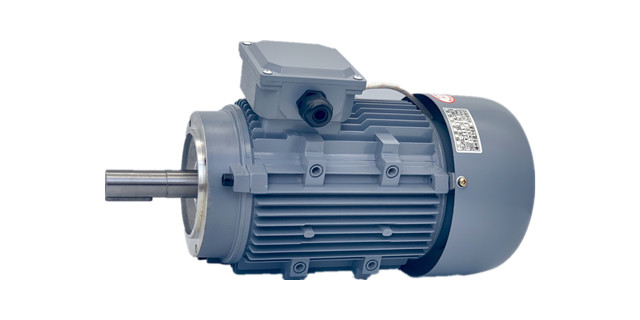

Shengzhou Senli Motor, yesBrake motor manufacturers, focus3KWResearch and development and production of the following low power motor, support can be providedOEM/ODMCustomization, specification customization, appearance customization, special shaft customization and color customization. We provide our customers with fast proofing service, complete quality inspection report and technical after-sales service. With reliable quality, reasonable price, excellent-The quality of service has been praised by the majority of users.

Customize the process: Understand the requirements-Provide parameters and drawings-Design scheme-Confirmation scheme-Confirm cooperation-Mass production-Deliver the goods-After-sales service; Can provideOEM/ODMCustomization, specification customization, appearance customization, special shaft customization and color customization.

Available if needed1688Search factory name "Shengzhou Chaoli Electric Appliance Factory" , Or online consultation message, we will have business personnel to get in touch with you, you can also contact us directly0575-8378-1127.

Long axis torque motor products, suitable for winding and winding scenarios, can be customized for different industry scenarios, to meet the requirements of use. This product produced by Senli has the characteristics of reasonable structure, high efficiency, good characteristics and long service life.

Shengzhou Senli Motor19Old motor manufacturers, with a number of their own motor production lines, from the shell, shaft, rotor, stator are independent production, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports. From the shaft machining to the whole machine assembly are completed independently. Truly realize factory direct sales.

Senli motor products are used180°High temperature resistance all copper coil material, torque motor products can be used with different rotors (ordinary rotors/Steel rotor), rotor of different motor characteristics are different, we from the shell, shaft, rotor, stator are produced by the independent, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports.