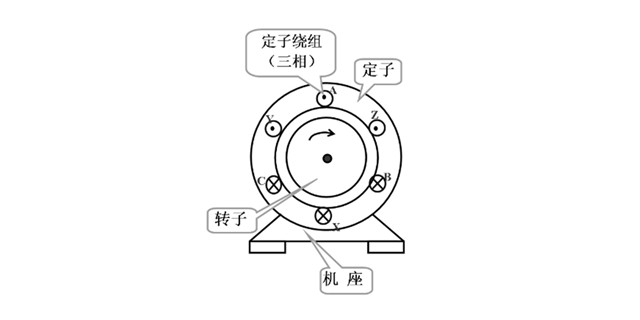

Production is mainly used AC motor, especiallyThree-phase asynchronous motorIt has the advantages of simple structure, robustness and durability, reliable operation and easy maintenance. Its two basic components can be divided into the stator is a fixed part and the rotor is a rotating part; There are also auxiliary parts such as end cover and fan, as shown in the following figure.

Stator coreBelong toThree-phase asynchronous motorA part of the magnetic circuit that is used because the main magnetic field rotates relative to the stator at a synchronous speed in order to reduce the loss caused in the core0.5mmThick, highly permeable silicon steel sheet with insulating paint on both sides to reduce eddy current losses in the core.

Engine bedAlso known as the casing, it is used to support the stator core, which also bears the wholeThree-phase asynchronous motorThe reaction force during the operation of the load, the heat generated by the internal loss can be released through the frame.Mori machineThe production of small power motor adopts aluminum casting press housing.

Rotor coreIt is part of the magnetic circuit of the motor. Different from the stator core punching, the rotor core punching is slotted on the outer circle of the punching, and many grooves of the same shape are uniformly formed on the outer cylinder of the stacked rotor core, and the rotor winding is placed.

Rotor windingIt is another part of the circuit that cuts the stator's magnetic field, generates an induced potential and current, and makes the rotor rotate under the action of the magnetic field. Its structure can be divided into two types: cage type and winding type. The two rotors have their own characteristics: the cage type is simple in structure, convenient in manufacture, economical and durable; The structure of the winding type is complex and expensive, but the rotor circuit can introduce external resistance to start and speed regulation performance.

The cage type is composed of a guide bar placed in the rotor groove and an end ring at both ends. To save steel and improve productivity, small powerThree-phase asynchronous motorThe guide bar and end ring are generally cast in molten aluminum at one time; The winding of the cage rotor closes itself, without being powered by an external power supply, and its shape is like a cage, so it is called the cage rotor.

The above content is composed ofThree-phase asynchronous motor manufacturersMori machineProvided, interested in this or want to know about our products can consult online message or call directly0575-8378-1127.

Long axis torque motor products, suitable for winding and winding scenarios, can be customized for different industry scenarios, to meet the requirements of use. This product produced by Senli has the characteristics of reasonable structure, high efficiency, good characteristics and long service life.

Shengzhou Senli Motor19Old motor manufacturers, with a number of their own motor production lines, from the shell, shaft, rotor, stator are independent production, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports. From the shaft machining to the whole machine assembly are completed independently. Truly realize factory direct sales.

Senli motor products are used180°High temperature resistance all copper coil material, torque motor products can be used with different rotors (ordinary rotors/Steel rotor), rotor of different motor characteristics are different, we from the shell, shaft, rotor, stator are produced by the independent, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports.