How to see if the motor is efficient? It mainly depends on whether its efficiency can meet the corresponding national standards under full load conditions. The factors that affect the efficiency of three-phase asynchronous motors are mainly divided into five aspects, that is, the five major losses of the motor are often said: stator loss, rotor loss, iron loss, wind friction loss and stray loss.

Today, we will briefly understand the loss of stator and rotor with Senli Motor. The stator loss is directly proportional to the stator current and the stator winding resistance. Rotor loss is directly proportional to rotor current and rotor winding resistance.

reduceAsynchronous motorThe stator loss can increase the cross section area of the stator slot. In the case of the same stator outer diameter, increasing the cross section area of the stator slot will reduce the magnetic circuit area and increase the magnetic density of the teeth. Increase the stator slot filling rate, which is good for low voltage small motor, the application of the best winding and insulation size, large wire cross-sectional area can increase the stator slot filling rate; Shorten the length of the end of the stator winding as far as possible, and the loss of the end of the stator winding accounts for the total loss of the winding1/4~1/2,The motor efficiency can be improved by reducing the length of winding end.

To reduce the rotor loss, we can reduce the rotor current from the two aspects of improving the voltage and motor power factors, or increase the rotor slot cross-sectional area; Reducing the resistance of the rotor winding, such as the use of thick wires and low resistance materials, this is more meaningful for small motors, because small motors are generally cast aluminum rotors, if the use of cast copper rotors, the total loss of the motor can be reduced10%~15%However, today's cast copper rotors require high manufacturing temperatures and technology is not yet popular, and their costs are higher than cast aluminum rotors15%~20%.

Mori machine,20Focus on the development and production of electric motors. Available if needed1688Search factory name "Shengzhou Chaoli Electric Appliance Factory" , Or online consultation message, we will have business personnel to get in touch with you, you can also contact us directly0575-8378-1127.

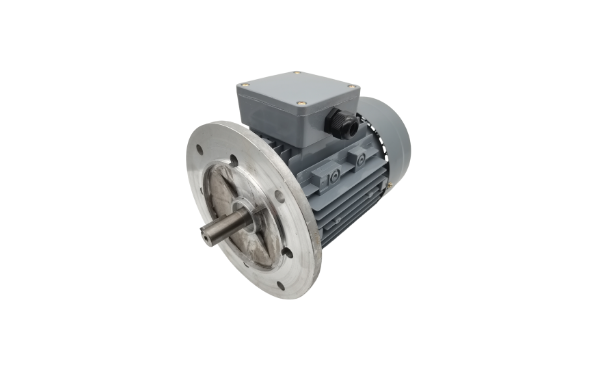

Long axis torque motor products, suitable for winding and winding scenarios, can be customized for different industry scenarios, to meet the requirements of use. This product produced by Senli has the characteristics of reasonable structure, high efficiency, good characteristics and long service life.

Shengzhou Senli Motor19Old motor manufacturers, with a number of their own motor production lines, from the shell, shaft, rotor, stator are independent production, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports. From the shaft machining to the whole machine assembly are completed independently. Truly realize factory direct sales.

Senli motor products are used180°High temperature resistance all copper coil material, torque motor products can be used with different rotors (ordinary rotors/Steel rotor), rotor of different motor characteristics are different, we from the shell, shaft, rotor, stator are produced by the independent, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports.