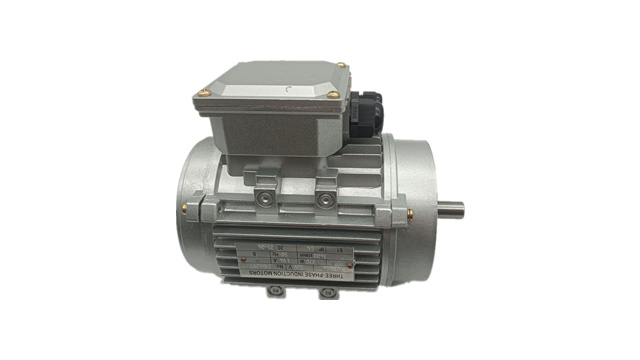

The operating principle of the torque motor is exactly the same as that of the general squirrel-cage asynchronous motor, but there are differences in structure, such as the use of materials with higher resistivity as the guide bar and end ring of the rotor, mainly because of the difference in characteristics, the rotor resistance will be much larger than the rotor resistance of the ordinary squirrel-cage motor. Let's take a look at this picture:

Details >

Torque motor is a special motor with a large number of poles, which can achieve low speed and gridlock, in such cases the motor does not kneel to cause damage, but can provide a relatively stable torque supply to the load, of course, it can also provide a torque in the opposite direction, we call the brake torque, its shaft is not a constant power output power but a constant torque output power.

Details >

We know that the variable frequency motor can use the frequency converter for speed regulation design, then the ordinary three-phase asynchronous motor can be variable frequency speed regulation? The answer is yes, to know that the inverter is not designed for the frequency conversion motor, the following and Senli motor Xiaobian together to understand the frequency conversion speed regulation of ordinary three-phase asynchronous motors.

Details >

Want to solve the three-phase asynchronous motor and other motor products are not burned out in the production process, the more effective way is to use the frequency converter, and now the brand of frequency converter technology is more mature, the quality is guaranteed, and the price can not be too expensive, compared with the occurrence of accidents, or burned out the motor is still more cost-effective.

Details >

Because the speed of the AC asynchronous motor is less than the speed of the rotating magnetic field, so we call the asynchronous motor, it should be basically the same motor, can be divided into induction motor and AC commutator motor, which induction motor is more widely used, can be divided into single-phase asynchronous motor, AC and DC dual-purpose motor and repulsion motor.

Details >

Asynchronous motor as a kind of AC motor, is widely used in small electromechanical equipment, its load speed and the frequency ratio of the power grid is not necessarily a constant relationship, will change with the size of the load, if the load torque is larger, then the speed will be lower, below and Senli motor Xiaobian together to understand it.

Details >

The asynchronous motor with single-phase AC power supply is called single-phase asynchronous motor, in the stator, in addition to its working winding, there will be a starting winding, the difference between the two is 90°, in the wiring, the starting winding series capacitor, with the working winding in parallel on the AC power supply, when the difference of 90 read the current into the space is also 90° after the two windings, the rotating magnetic field is generated.

Details >

Energy consumption braking is a widely used electrical braking method. When the motor is separated from the three-phase AC power supply, the DC power supply is immediately connected to the two-phase winding of the stator, and the DC current flows through the winding to produce a stationary DC magnetic field. Below and three-phase asynchronous motor manufacturers Senli motor together to understand the next.

Details >

Feedback braking is one of the braking methods of frequency converter, and it is also a very effective energy-saving method. And avoid the damage to the environment and equipment during braking. When the rotor speed of the three-phase asynchronous motor is higher than the synchronous speed of the stator magnetic field, the direction of the electromagnetic torque is opposite to the rotor steering, and the motor both returns electrical energy and generates mechanical braking torque on the shaft, that is, it runs in the braking state.

Details >

In the production process, we often need to take some measures to make the three-phase asynchronous motor stop as soon as possible, or from a high speed to a low speed operation, or limit the potential energy load to run stably at a certain speed, which can be achieved by mechanical braking and electromagnetic braking.

Details >

Long axis torque motor products, suitable for winding and winding scenarios, can be customized for different industry scenarios, to meet the requirements of use. This product produced by Senli has the characteristics of reasonable structure, high efficiency, good characteristics and long service life.

Shengzhou Senli Motor19Old motor manufacturers, with a number of their own motor production lines, from the shell, shaft, rotor, stator are independent production, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports. From the shaft machining to the whole machine assembly are completed independently. Truly realize factory direct sales.

Senli motor products are used180°High temperature resistance all copper coil material, torque motor products can be used with different rotors (ordinary rotors/Steel rotor), rotor of different motor characteristics are different, we from the shell, shaft, rotor, stator are produced by the independent, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports.