Y series three-phase asynchronous motors attach a DC disc electromagnetic brake between the rear end cover and the fan to form the brake motor, which is a fully enclosed self-fan-cooled squirrel cage type three-phase asynchronous motor with an additional disc DC brake, so we list it as a derivative series of Y series motors.

Details >

The cooling fan is the key component of the torque motor product, which achieves the cooling effect by forced air cooling, so the reliability of the quality is particularly important. The cooling fan is independently powered by the 380V/50HZ power frequency power supply, and the power of the fan comes from a separate power supply, which cannot be sent out from the main motor. Let's take a simple look at the wiring of the fan.

Details >

In order to better play a role in production, we should also pay attention to some matters when using the brake motor, so that the product can better assist production. After the brake motor is configured in the selection, what should we pay attention to? Here is a simple understanding with Senli Motor Xiaobian.

Details >

We know that the synchronous speed is divided by the logarithm of the magnetic pole P, and the principle of motor speed selection is to make it as close as possible to the speed of the production machinery to simplify the transmission device. Three-phase asynchronous motor speed is close to synchronous speed, if you want to adjust its speed, you can use to change the power frequency f, change the slip rate S and change the magnetic field pole log P and other three methods.

Details >

In order to ensure the stable operation of the equipment, the installation of wiring is an important work. Before the torque motor wiring, we should understand the wiring circuit diagram in the design drawing and connect the wiring according to the mark in the junction box. So what should we pay attention to when wiring the torque motor? Here is a simple understanding with Senli Motor Xiaobian.

Details >

Because the current is too large, single-phase operation will cause insulation damage of three-phase asynchronous motor. If the motor is in long-term overload, it will accelerate the aging of the motor insulation, thus losing the insulation effect, which will cause the coil to heat rapidly, thus burning the motor. Here is a simple understanding of this content with Senli Motor Xiaobian.

Details >

The choice of installation site is each motor should be considered, if improper selection, will shorten the life of the motor product, resulting in frequent failures; Therefore, when we install the brake motor, we need to take into account these factors, and the following is a simple understanding of the Senli motor Xiaobian.

Details >

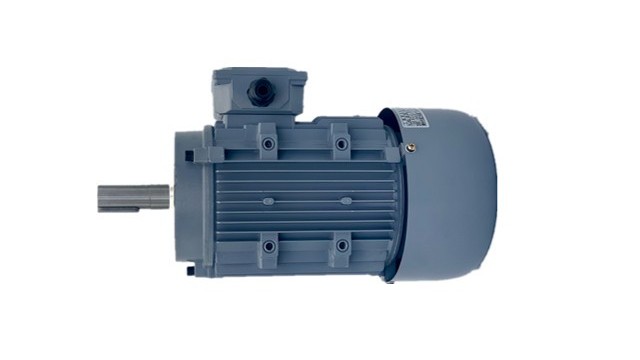

Shengzhou Chaoli Electric Appliance Factory, brand "Senli"; Committed to the development and manufacturing of high-efficiency motor products, the company's main products are three-phase asynchronous motor, torque motor, brake motor, single-phase asynchronous motor, DC brushless motor and other series; It can be customized according to the actual needs of customers, and each motor has been strictly inspected before leaving the factory. Senli Motor provides a variety of customization services: specification customization, appearance customization, special shaft customization and color customization.

Details >

Taking the operating conditions of the three-phase asynchronous motor produced by Senli as an example, the ambient air temperature does not exceed 40 ° C with the season, the minimum temperature does not exceed -15 ° C, and the altitude does not exceed 1000m. At what temperature can it operate properly? Here is a simple understanding with Senli Motor Xiaobian.

Details >

When the motor is operating, we all hope that it can play a maximum role, which will lead many manufacturers to irregular operation, resulting in three-phase asynchronous motor load operation, resulting in motor temperature rise, thereby damaging the motor. The following play and Senli motor Xiaobian together with a simple understanding.

Details >

Long axis torque motor products, suitable for winding and winding scenarios, can be customized for different industry scenarios, to meet the requirements of use. This product produced by Senli has the characteristics of reasonable structure, high efficiency, good characteristics and long service life.

Shengzhou Senli Motor19Old motor manufacturers, with a number of their own motor production lines, from the shell, shaft, rotor, stator are independent production, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports. From the shaft machining to the whole machine assembly are completed independently. Truly realize factory direct sales.

Senli motor products are used180°High temperature resistance all copper coil material, torque motor products can be used with different rotors (ordinary rotors/Steel rotor), rotor of different motor characteristics are different, we from the shell, shaft, rotor, stator are produced by the independent, all products are the use of professional product quality supervision and testing equipment full inspection factory, can provide testing reports.