Motor customization processcustomization process

Obtain requirements

Obtain requirements provide parameters

provide parameters design proposal

design proposal confirm proposal

confirm proposal confirm cooperation

confirm cooperation mass production

mass production Product acceptance

Product acceptance after service

after service

Hot keywords:

High temperature resistant operation

High temperature resistant operation

The insulation level of the motor can be customized according to customer requirements (E level, B level, H level, F level)

High precision level

High precision level

Rotor dynamic balance<200 milligrams, shaft concentricity control<5 threads.

Lightweight and beautiful

Lightweight and beautiful

Aluminum die-casting shell, with a small specific gravity, light weight, non perishable, and long service life!

Source quality control

Source quality control

The shell, shaft, rotor, and stator are all independently produced to ensure quality from the production source.

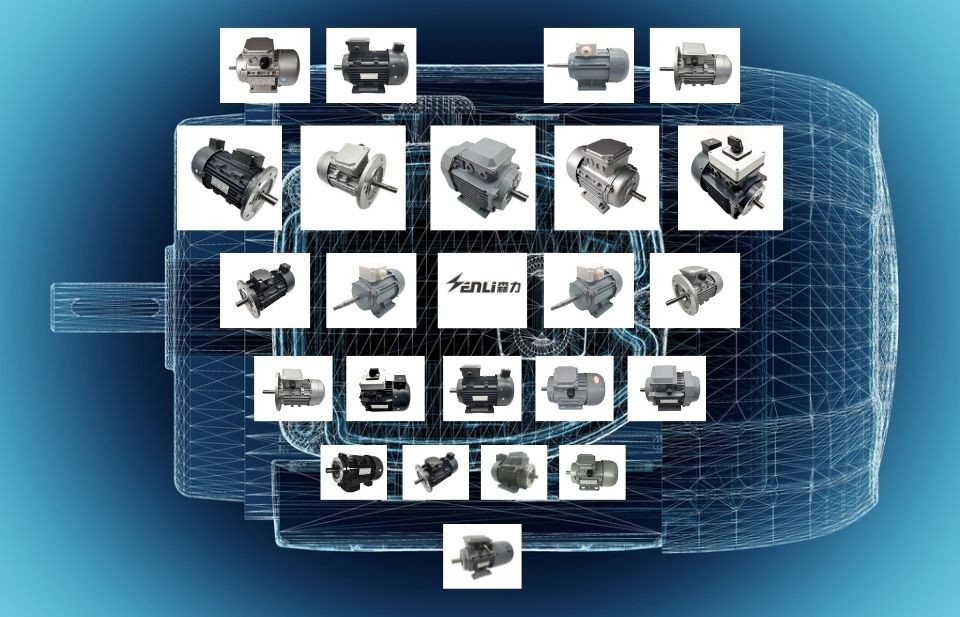

Technology R&D

Technology R&DSenli Motor allocates over 1 million RMB annually for research and development purposes. These funds are primarily directed towards the acquisition of advanced experimental equipment and the implementation of comprehensive staff training programs. As a result of such investments, the company manages to roll out more than 15 novel motor products each year. Moreover, Senli Motor has been granted over 20 patents and software copyright certifications.

Customized

CustomizedMotor performance can be customized according to the usage requirements of the equipment host, providing customized solutions for motor power, performance parameters, insulation level, installation method, specifications, etc.

Manufacture

ManufactureWe have a standardized factory building of 8500 square meters and lean manufacturing equipment such as CNC lathes, dynamic balancing machines, and magnetic punching machines. Annual production capacity of 300000 units.

Services

ServicesSenli Motor promises a one-year warranty and lifetime maintenance. 24-hour response to customer needs, providing technical online Q&A, providing solutions within half an hour, and offering on-site support within 24 hours.

Let us customize motors for you

WC+86 17816180570

Online consultation

WC+86 17816180570

Online consultation

We began to cooperate with Senli brushles...

Obtain requirements

Obtain requirements provide parameters

provide parameters design proposal

design proposal confirm proposal

confirm proposal confirm cooperation

confirm cooperation mass production

mass production Product acceptance

Product acceptance after service

after service

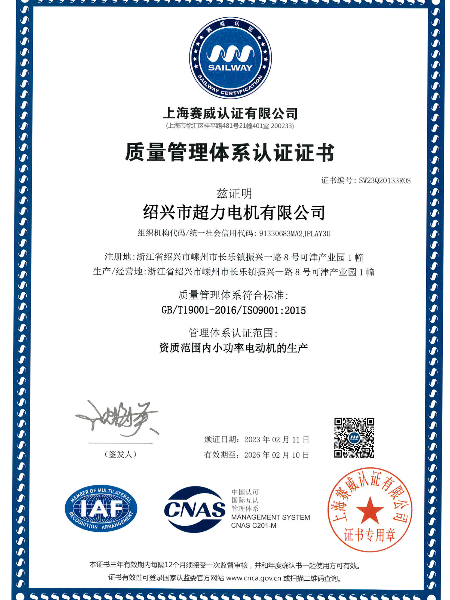

Senli Motor ISO9001 certificate

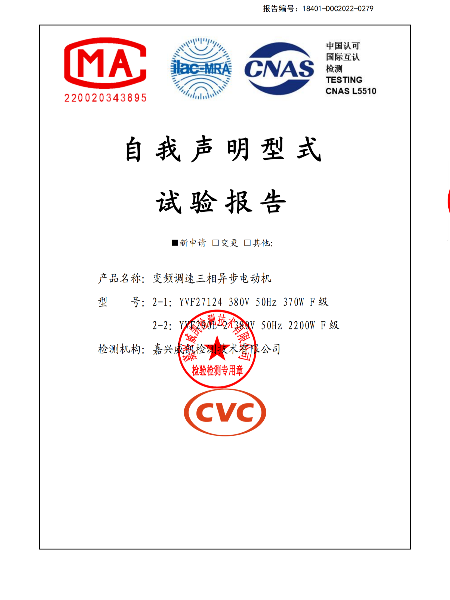

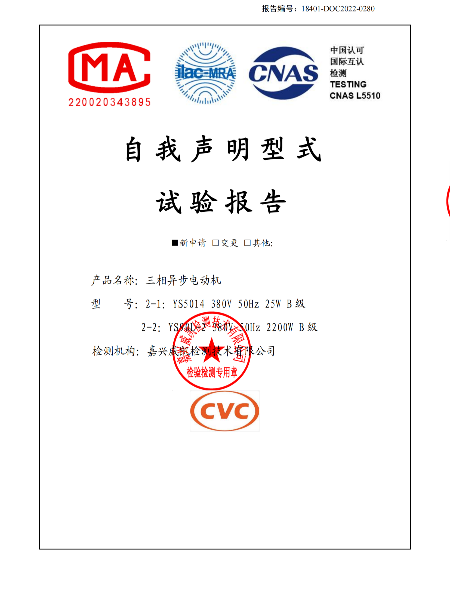

Senli Motor ISO9001 certificate Variable frequency speed regulating three-phase asynchronous motor 3C self-declaration

Variable frequency speed regulating three-phase asynchronous motor 3C self-declaration Electromagnetic brake three-phase asynchronous motor 3C self-declaration

Electromagnetic brake three-phase asynchronous motor 3C self-declaration Capacitor operation asynchronous motor 3C Self-declaration

Capacitor operation asynchronous motor 3C Self-declaration Torque three-phase asynchronous motor 3C self-declaration

Torque three-phase asynchronous motor 3C self-declaration Dual DC capacitor asynchronous motor 3C self-declaration

Dual DC capacitor asynchronous motor 3C self-declaration Three-phase asynchronous motor 3C self-declaration

Three-phase asynchronous motor 3C self-declaration